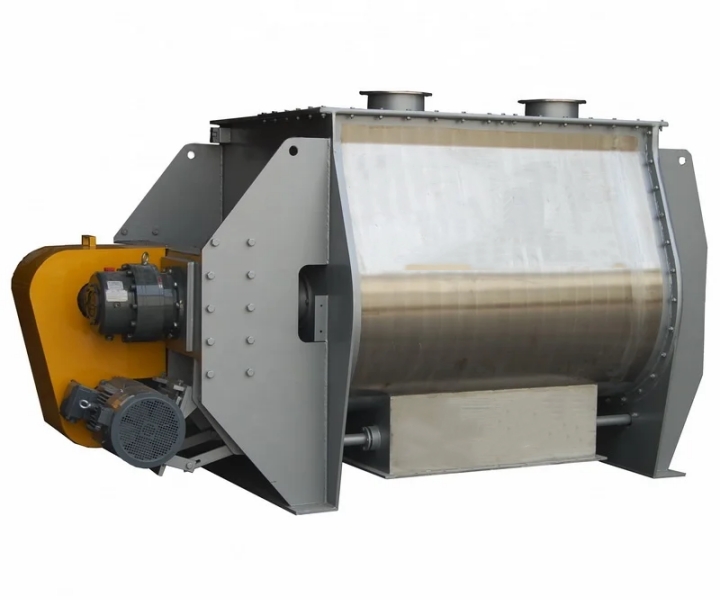

An equipment for mixing materials efficiently, quickly and evenly. It is easy to operate, has good mixing effect and has a wide range of applications.

![]()

![]()

Price:$1,000.00-$7,900.00/Set

Consult now and enjoy a 10% discount

One-time mixing: 100-6000kg

Mixing time:: 8-20min

Mixing speed: 15-60r/min

Voltage:: 220V/380V/customize

Weight:: 500-7500kg

Application: It can be used to mix powdery and granular materials, including chemicals, food additives, drugs, ores, metallurgical powders, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Airflow Mixer is a device used for mixing materials. It uses the action of airflow to evenly mix different granular or powdery materials together. It uses the shear force and convection effect generated by the air flow to quickly mix the materials inside the equipment and achieve a uniform state. An airflow mixer usually consists of a rotating mixing chamber and a high-speed airflow generator. By adjusting the speed and direction of the airflow, rapid mixing of materials is achieved.

Airflow mixers offer many advantages. First, it can achieve an efficient mixing process and greatly improve production efficiency. Secondly, the airflow mixer can evenly mix different granular or powdery materials to ensure that each particle is fully contacted and mixed, thereby improving the uniformity and quality stability of the product. In addition, the airflow mixer has the characteristics of simple structure, convenient operation, and easy cleaning. It is suitable for a variety of industries, such as chemical industry, food, pharmaceutical, etc., and is widely used in the mixing, drying and homogenization of granular materials.

Common blades in airflow mixers are mainly divided into three categories: paddle blades, spiral blades and knife blades.

Paddle blades

Paddle blades are flat, similar to the shape of a boat oar. They provide a large mixing area and are suitable for mixing more viscous materials. They can effectively shear and stir the materials to make them evenly mixed. Paddle blades are commonly used in chemical, pharmaceutical and food processing industries.

Spiral blades

Spiral blades are spiral-shaped, similar to a propeller. They produce strong vortex and shear effects in the airflow mixer, which can effectively push and mix materials. Spiral blades are often used for mixing high-viscosity materials, such as colloids, slurries, etc., and are suitable for chemical, pharmaceutical, coating and other fields.

Knife blades

Knife blades are flat and similar to the shape of a razor blade. They have large shearing force and cutting action, and can effectively cut and mix materials. Knife blades are commonly used in applications requiring a high degree of shear and dispersion, such as in the rubber, plastics and paint industries.

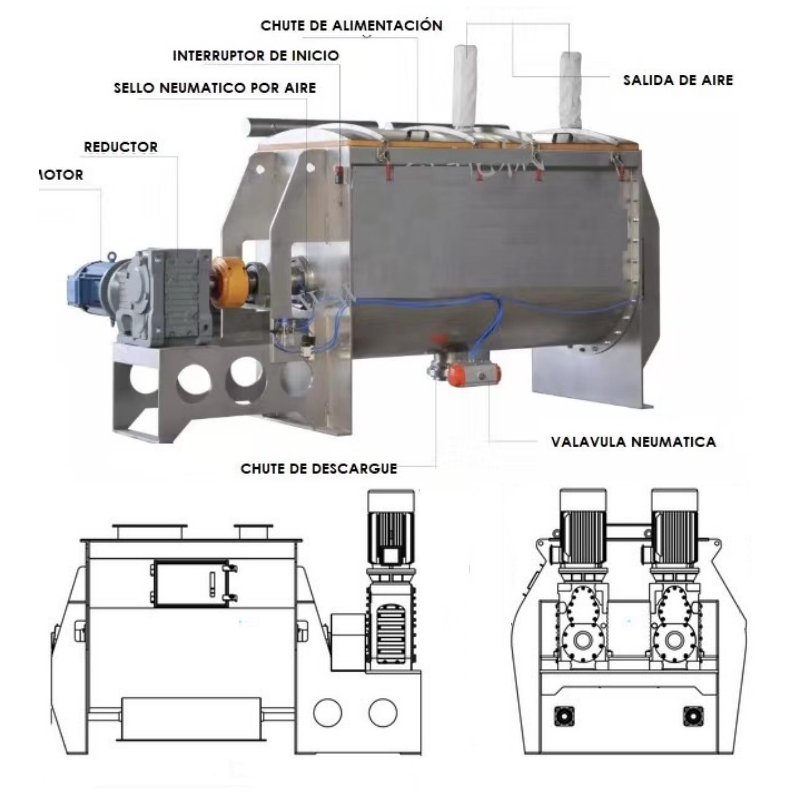

Airflow mixers usually consist of the following main parts:

Mixing chamber: The mixing chamber is the main working area of the airflow mixer, usually a cylindrical or conical container. Materials enter the mixing chamber through the feed port and are mixed there. There are usually specially designed stirring devices inside the mixing chamber, such as rotating blades or airflow nozzles, to increase the mixing effect of the materials.

High-speed airflow generator: The high-speed airflow generator is used to generate powerful airflow to suspend materials and push them to move inside the mixing chamber. Air flow generators are typically powered by compressed air or other gas sources and introduce air flow into the mixing chamber through a nozzle or outlet.

Control system: Airflow mixers are usually equipped with a control system to adjust the speed and direction of the airflow to control the time and intensity of the mixing process. The control system can perform automated control as needed to ensure the consistency and stability of the mixing process.

The working principle of the airflow mixer is to uniformly mix different granular or powdery materials together through the action of airflow. It uses the shear force and convection effect generated by the air flow to quickly mix the materials inside the equipment and achieve a uniform state.

During operation, materials enter the mixing chamber through the feed port, and at the same time, the high-speed airflow generator generates strong airflow to suspend the materials and push them to move inside the mixing chamber. The material generates shear force and convection effect under the action of air flow, constantly collides and mixes with other materials, and finally reaches a uniform mixing state. The mixed materials are discharged through the discharge port to complete the mixing process.

Airflow mixers are widely used in many fields. The following are some scenarios for airflow mixers:

Food Industry: Airflow mixers can be used for dry mixing, homogenization and mixing processes in food processing. For example, in the baking industry, airflow mixers can be used to evenly mix flour, powdered sugar, cocoa powder and other dry powder ingredients to ensure product consistency and quality.

Chemical industry: Airflow mixers are often used in the mixing and drying process of granular materials in chemical production. For example, in fertilizer production, airflow mixers can mix fertilizer particles of different compositions to obtain a balanced nutrient ratio.

Pharmaceutical Industry:Airflow mixers play an important role in pharmaceutical processes for mixing and uniformly dispersing powdered pharmaceutical raw materials. This helps ensure the uniformity and stability of the drug to meet quality requirements for drug production.

Metallurgical industry: Airflow mixers are often used in the metallurgical field to mix particulate materials in the smelting process. For example, in the steelmaking process, airflow mixers can mix different types of iron ore and additives to obtain the required steelmaking raw material ratio.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Efficient mixing

The airflow mixer can generate shear force and convection effect through powerful airflow to quickly mix the materials evenly. Compared with traditional mixing equipment, airflow mixers have higher mixing efficiency and shorter mixing time.

Good uniformity

The airflow mixer can evenly mix different granular or powdery materials together to ensure that the mixed product has consistent composition and quality. Good mixing uniformity is very important to ensure the stability of product quality.

Easy operation

Airflow mixers usually have a simple structure and operation mode, making them easy to use and maintain. The operator only needs to control the speed and direction of the air flow to control the mixing process without complicated adjustments and operating steps.

Wide scope of application

The airflow mixer is suitable for mixing a variety of materials, including granules, powders, granules and powders, etc. It can be used in food, chemical, pharmaceutical, metallurgy and other industries to meet the mixing needs of different industries.

Low energy consumption

Compared to other mixing equipment, airflow mixers generally have lower energy consumption. It uses the power of air flow for mixing without additional energy consumption, reducing production costs and having less impact on the environment.

Strong scalability

The airflow mixer can be expanded and customized according to production needs. According to different process requirements and production scale, the size of the mixing chamber, the number and layout of the air flow generators can be adjusted to meet different production needs.

A food processing company needs to uniformly mix a variety of powdered raw materials during the production process to ensure the quality and taste of the product. In order to improve mixing efficiency and ensure mixing consistency, they chose an efficient airflow mixer. The air flow mixer adopts advanced air flow dynamics design, which uses strong air flow to generate shear force and convection effect to quickly mix different powdery raw materials evenly. Airflow mixers help the food processing company achieve efficient mixing, improving product uniformity and quality stability.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.