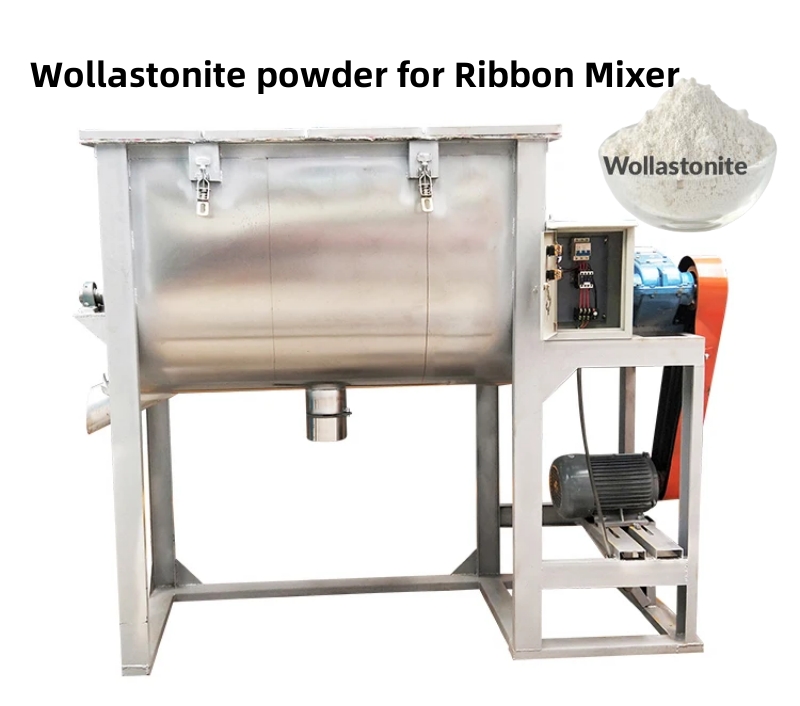

Ribbon mixer is a common industrial mixing equipment, widely used in chemical industry, building materials, metallurgy and other industries. In the building materials industry, wollastonite powder is an important raw material and is widely used in the production of concrete, cement, mortar and other products. This article will explore the application of ribbon mixers in the production of wollastonite powder and its importance in improving product quality and production efficiency.

First of all, wollastonite is a common mineral whose main components are silicon dioxide (SiO2) and calcium oxide (CaO). After wollastonite is processed through crushing, grinding and other processes, fine wollastonite powder can be obtained. Wollastonite powder has fine particles and high activity, and is one of the important raw materials for manufacturing high-performance building materials products.

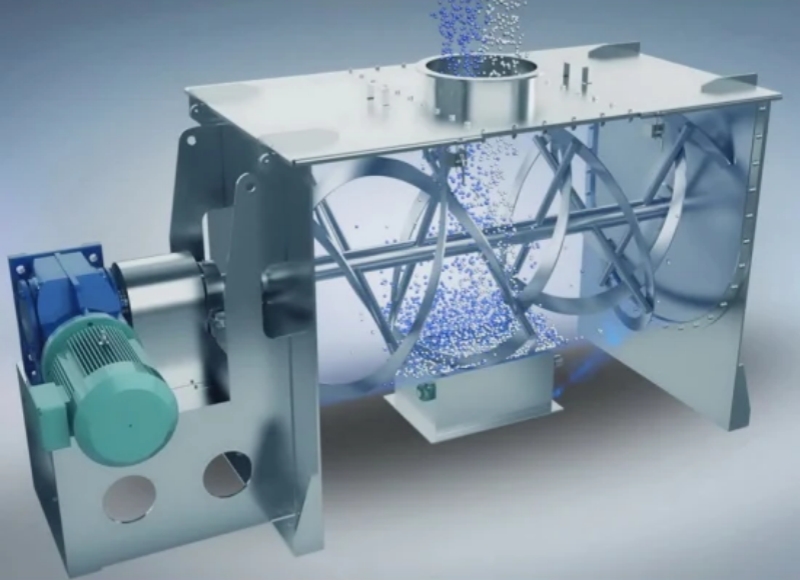

Ribbon mixer plays an important role in the production of wollastonite powder. First of all, the ribbon mixer can fully mix the various components of wollastonite powder. The equipment adopts a spiral blade design to evenly mix wollastonite powder with other ingredients through rotational motion to ensure uniform distribution between particles. This is very important to ensure the quality and stability of wollastonite powder and avoid uneven distribution and agglomeration of ingredients.

Secondly, the ribbon mixer can also humidify wollastonite powder. Humidification is the process of thoroughly mixing powdery materials with liquid to turn them into moist paste materials. In the production of wollastonite powder, humidification treatment is a very critical step, which can improve the solubility and flowability of wollastonite powder, making it easier to process and apply. The ribbon mixer uses strong shearing force and stirring effect to fully mix wollastonite powder and liquid to form a moist paste material, which facilitates subsequent drying and molding.

In addition, the ribbon mixer can also homogenize wollastonite powder. Homogenization is a process in which materials undergo high-speed stirring and shearing to make their particle size more uniform and finer. In the production of wollastonite powder, homogenization treatment can further improve the uniformity and fineness of the product, making it more suitable for various application fields. The ribbon mixer has good shearing and stirring effects and can homogenize wollastonite powder particles to improve product quality and application performance.

In the production of wollastonite powder, through the mixing, humidification and homogenization treatment of the ribbon mixer, the components of wollastonite powder can be evenly dispersed, improving the quality and stability of the product. It can also facilitate the subsequent processing of wollastonite powder, such as drying, molding, etc. It can fully mix wollastonite powder and liquid to achieve humidification and homogenization, providing high-quality raw materials for subsequent processes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.