Rotary drum feed mixer is equipment used for poultry feed production. It uses a rotating drum and stirring device to fully mix the feed ingredients to ensure uniformity of the formula. The working principle is to put the raw materials into the drum, and the stirring device mixes the raw materials when the drum rotates. This kind of machine improves production efficiency and ensures feed quality, and is an indispensable key equipment in poultry feed production. The following is a detailed introduction to the working principle and workflow of rotary drum feed mixer:

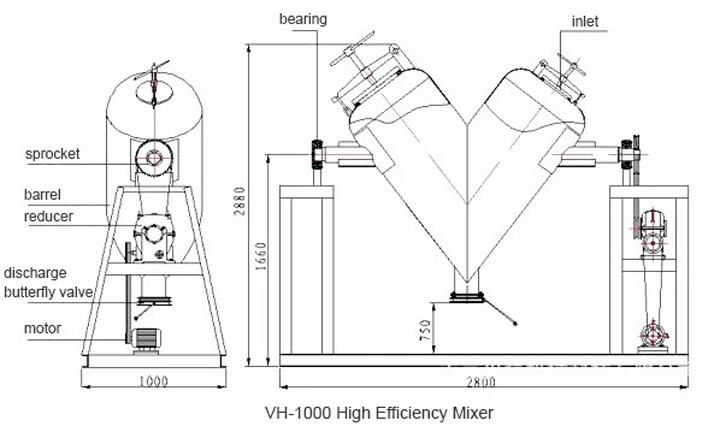

Rotary drum feed mixer usually consists of a cylindrical drum with a stirring device inside.

The drum is fixed on the frame and driven to rotate by the driving device.

The stirring device usually consists of stirring blades or stirring arms, which are installed inside the drum.

When the drum is driven to rotate, the mixing device also rotates to continuously mix the feed ingredients.

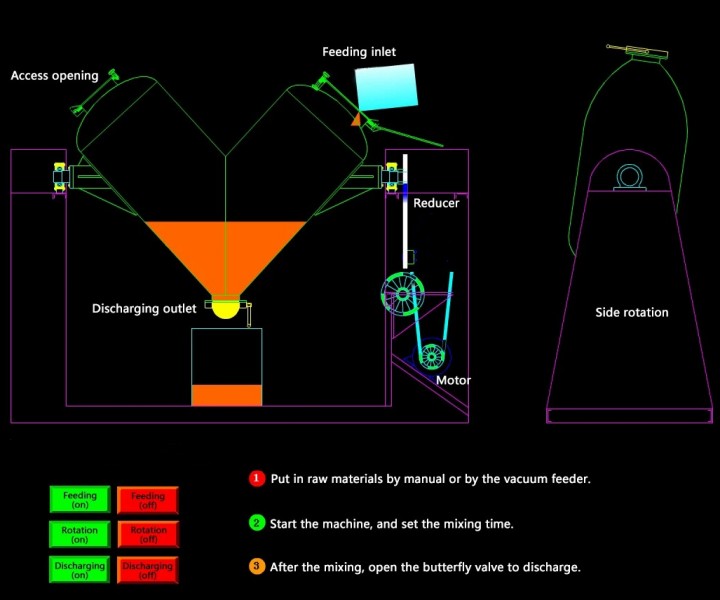

Put the poultry feed ingredients to be mixed into the drum according to the formula proportion.

When the drum starts to rotate, the mixing device continuously stirs and turns the feed ingredients so that the raw materials are fully mixed inside the drum.

Through the action of the mixing device, granules, powders and liquid raw materials are evenly mixed to ensure the consistency of the feed formula.

Within the set mixing time, the feed ingredients are fully mixed and the mixed feed can be taken out through the discharge port.

Check the status of the equipment and confirm that the equipment is safe and reliable.

Prepare the poultry feed ingredients that need to be mixed according to the recipe requirements.

Put the prepared feed ingredients into the drum according to the formula proportion.

Start the rotary drum feed mixer and set the mixing time and speed.

The drum starts to rotate and the mixing device starts to work to mix the feed ingredients.

The stirring device continuously stirs and turns the raw materials to ensure even mixing.

During the mixing process, monitor the mixing to ensure that the feed ingredients are fully mixed.

After the set mixing time has elapsed, stop the equipment.

Open the outlet and take out the mixed poultry feed.

Clean the inside of the rotary drum feed mixer to ensure equipment hygiene.

Perform regular maintenance on the equipment to extend its service life.

Rotary drum feed mixer achieves uniform mixing of poultry feed ingredients through the synergy of the rotating drum and stirring device, improving feed production efficiency and product quality. This equipment plays an important role in poultry feed production, providing a reliable mixing solution for producing high-quality, nutritionally balanced poultry feed.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.