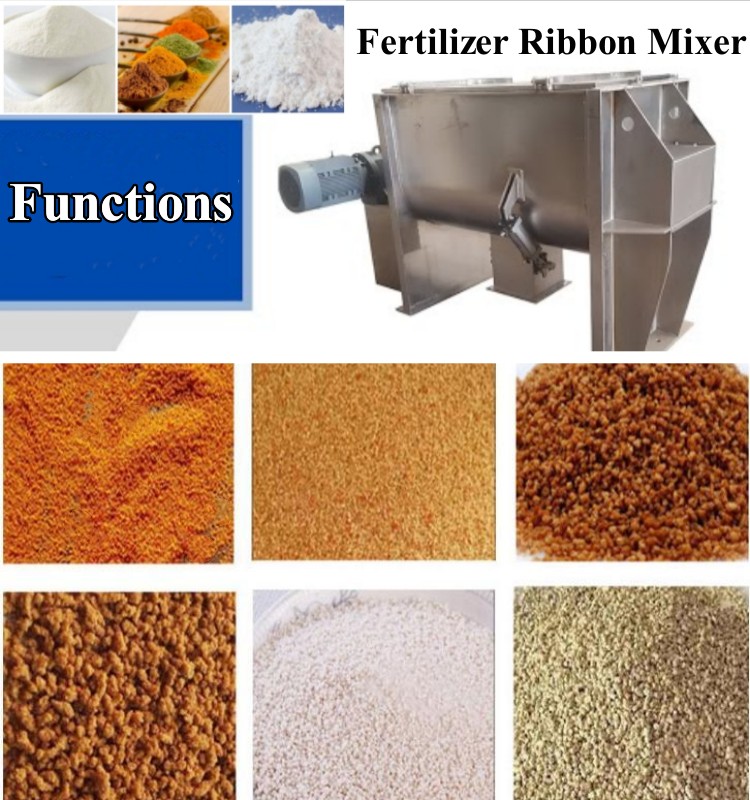

Fertilizer ribbon mixer is a commonly used mixing equipment that is widely used in fertilizer production and processing processes. What is the function of fertilizer ribbon mixer? Its main function is to mix fertilizer raw materials of different compositions and particle sizes to achieve uniformity and consistency requirements. The function of the fertilizer ribbon mixer will be introduced in detail below.

The structure of the fertilizer ribbon mixer mainly includes a mixing barrel, ribbon, transmission device and discharge port. The ribbon is located inside the mixing barrel. Driven by the transmission device, the ribbon moves in a spiral shape to fully mix the fertilizer raw materials.

Uniform mixing: The fertilizer ribbon mixer can evenly mix fertilizer raw materials with different compositions and particle sizes. The spiral motion of the ribbon transports the raw materials from one end of the mixing barrel to the other, causing the raw materials to continuously cross and overlap during the movement, thereby achieving mixing. This ensures that the different fertilizer ingredients are thoroughly mixed so that the final product has a uniform composition and particle distribution.

Improve fertilizer quality: Through mixing, the fertilizer ribbon mixer can make the ingredients and particles of fertilizer raw materials more evenly distributed, thereby improving the quality of fertilizer. Uniform mixing can ensure that the fertilizer ingredients produced in each batch are consistent and avoid differences in fertilizer efficiency caused by uneven ingredients. At the same time, mixing can also reduce the particle dispersion of fertilizers, making it easier to spread the fertilizer evenly during application and improving the fertilization effect.

Improve production efficiency: The fertilizer ribbon mixer has a large processing capacity and can meet the mixing needs of large quantities of fertilizers. The mixing process is carried out through the continuous movement of the ribbon, which is highly efficient and stable. At the same time, the mixer has a reasonable structural design and is easy to operate and maintain, which can reduce labor and time costs in the production process and improve production efficiency.

Adaptable to a variety of fertilizers: The fertilizer ribbon mixer is suitable for mixing many types of fertilizer raw materials. Whether it is organic fertilizer, inorganic fertilizer, or compound fertilizer and other different types of fertilizers, effective mixing can be achieved by adjusting the operating parameters of the mixer and the design of the ribbon. This flexibility allows the mixer to be adapted to different production requirements and process flows.

Reduce production costs: By using a fertilizer ribbon mixer, you can reduce production costs. The mixing process of the mixer is continuous, without the need for additional processes and equipment, saving time and energy in the production process. At the same time, uniform mixing can reduce fertilizer waste and loss, improve utilization and reduce production costs.

To sum up, the fertilizer ribbon mixer plays a key role in the fertilizer production and processing process. By mixing fertilizer raw materials with different compositions and particle sizes, it achieves uniformity and consistency of mixing, improves fertilizer quality and production efficiency, and reduces production costs. It is one of the indispensable equipment in the fertilizer production process and is of great significance for improving the quality and efficiency of fertilizer production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.