V-type powder mixer, also known as a V-shaped powder mixer or V blender, is a type of industrial mixing equipment commonly used in the pharmaceutical, food, chemical, and other industries for blending dry powders and granules.

V-type mixers are suitable for mixing powders and granules with good fluidity and small differences in physical properties. Since the materials in the V-type mixing container flow smoothly and will not damage the original shape of the materials, they are also suitable for mixing granular materials that are easy to break and wear, or for mixing finer powders, lumps, and materials containing a certain amount of water. The use of V-type mixers not only improves production efficiency, but also ensures the consistency of product quality. Therefore, they are widely used in the pharmaceutical, chemical, food and other industries.

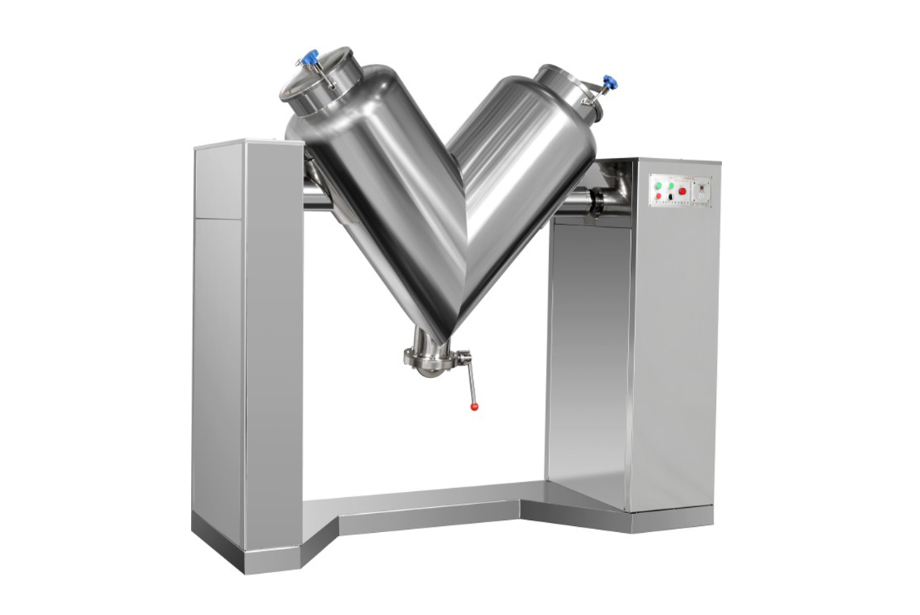

V-Shaped Mixing Chamber: The mixer features a V-shaped chamber with two asymmetrically positioned cylinders that form a V shape. This design helps in efficient mixing and prevents material accumulation in the corners.

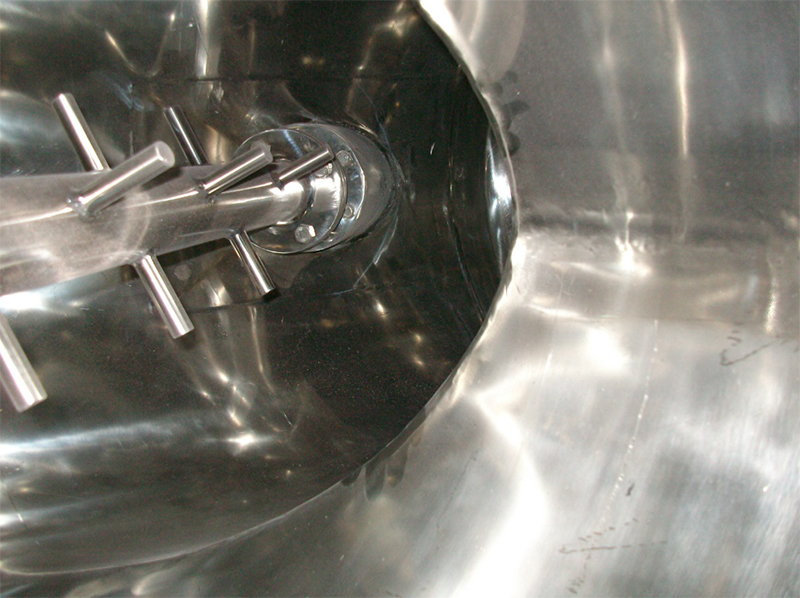

Rotating Mixing Blades: Inside the chamber, there are typically two or more rotating blades that move the material in a three-dimensional motion, ensuring thorough blending.

Drive System: The mixer is powered by an electric motor that drives the rotation of the mixing blades. The speed and direction of rotation can often be adjusted to achieve the desired mixing effect.

Discharge Valve: At the bottom of the chamber, there is a discharge valve that allows for easy removal of the blended material after mixing is complete.

Gentle Mixing: The V-type powder mixer is known for its gentle mixing action, which is crucial for preserving the integrity of fragile materials and preventing excessive heat generation during blending.

Homogeneous Mixing: The mixer ensures a high level of homogeneity by effectively combining different powders or granules into a uniform mixture.

Short Mixing Time: Due to the efficient design and mixing mechanism, V-type powder mixers can achieve thorough blending in a relatively short period, increasing production efficiency.

No Dead Zones: The V-shaped chamber design eliminates dead zones where materials can accumulate, ensuring that all particles are consistently mixed.

Versatility: V-type powder mixers are versatile and can handle a wide range of materials, including powders, granules, and even some pastes.

Easy to Clean: The design of the mixer allows for easy cleaning and maintenance, reducing downtime between batches.

Low Energy Consumption: These mixers are known for their energy efficiency, making them cost-effective for continuous use in industrial settings.

Scalability: V-type powder mixers come in various sizes, allowing for scalability to meet different production requirements.

Pharmaceutical Industry: Used for blending powders for medication production, ensuring uniform distribution of active ingredients.

Food Industry: Ideal for mixing dry ingredients in the production of food products such as spices, seasonings, and nutritional supplements.

Chemical Industry: Commonly employed for blending chemical powders and additives for manufacturing processes.

Cosmetics Industry: Used for mixing ingredients in the production of cosmetics and personal care products.

V-type powder mixer is a reliable and efficient solution for achieving homogeneous blending of dry powders and granules in various industries. Its unique design, gentle mixing action, and versatility make it a valuable asset for production processes requiring consistent and high-quality mixing results.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.