Spices ribbon mixer is specially designed for mixing spices, herbs, seasonings and other powdered ingredients. The mixer adopts a double spiral ribbon blade design, which can move materials in both directions to ensure thorough mixing.

Spices ribbon mixer is suitable for mixing various types of spices, including but not limited to the following types of spices:

Powdered spices: such as chili powder, curry powder, five-spice powder and other powdered spices.

Granular spices: such as cloves, fennel seeds, peppercorns and other granular spices.

Block spices: Some large block spices such as cinnamon bark, dried ginger blocks, etc. can also be mixed by spiral ribbon mixer.

Fresh spices: Some fresh spices such as chopped onion, ginger and garlic can also be mixed by spiral ribbon mixer under appropriate circumstances.

The design of the spice spiral ribbon mixer makes it suitable for spices of various shapes and types. Through the mixing action of the spiral ribbon, the spices can be evenly mixed, thereby ensuring the consistency and quality of the final mixture.

In practical applications, spices ribbon mixers can be used in various scenarios and industries. Here are some possible application sites:

Food processing factories: In the food industry, spices ribbon mixers are often used to mix various spices and seasonings, such as mixing chili powder, curry powder, five-spice powder, etc., to ensure uniform distribution and consistency.

Seasoning production: Seasoning manufacturers can use spices ribbon mixers to mix various spices, flavors and other raw materials to produce seasonings with balanced taste.

Drug manufacturing: In the pharmaceutical industry, spices ribbon mixers can be used to mix drug ingredients, additives and other powdered raw materials to ensure the uniformity and consistency of drugs.

Cosmetic production: The cosmetics industry usually needs to mix various pigments, spices and other ingredients. Spice ribbon mixers can ensure that these ingredients are evenly mixed.

Feed processing: In animal husbandry and pet food production, spice ribbon mixers can be used to mix various feed additives, vitamins and minerals to improve the nutritional value of feed.

Chemical industry: Some chemical companies may also use spice ribbon mixers to mix powdered raw materials for the production of chemical products or additives.

Efficient mixing: Ribbon blenders are known for their ability to efficiently blend a wide range of ingredients. The ribbon agitator helps move the materials in multiple directions within the mixing chamber, ensuring a uniform blend.

Gentle mixing action: Ribbon blenders provide gentle mixing action, which is very important when blending fine spices as they should not be over-mixed to maintain their quality.

Customizable design: Ribbon blenders can be customized to the specific requirements of blended spices. The size, shape, and speed of the ribbon can be adjusted to achieve the desired blending effect.

Sanitary design: Many ribbon blenders are designed with easy cleaning in mind, making them suitable for food processing applications such as blending spices.

Batch or continuous blending: Ribbon blenders can be used for both batch and continuous blending operations, depending on the production requirements.

Blending uniformity: Ribbon blenders provide excellent blending uniformity, ensuring that all spices are evenly distributed in the blend.

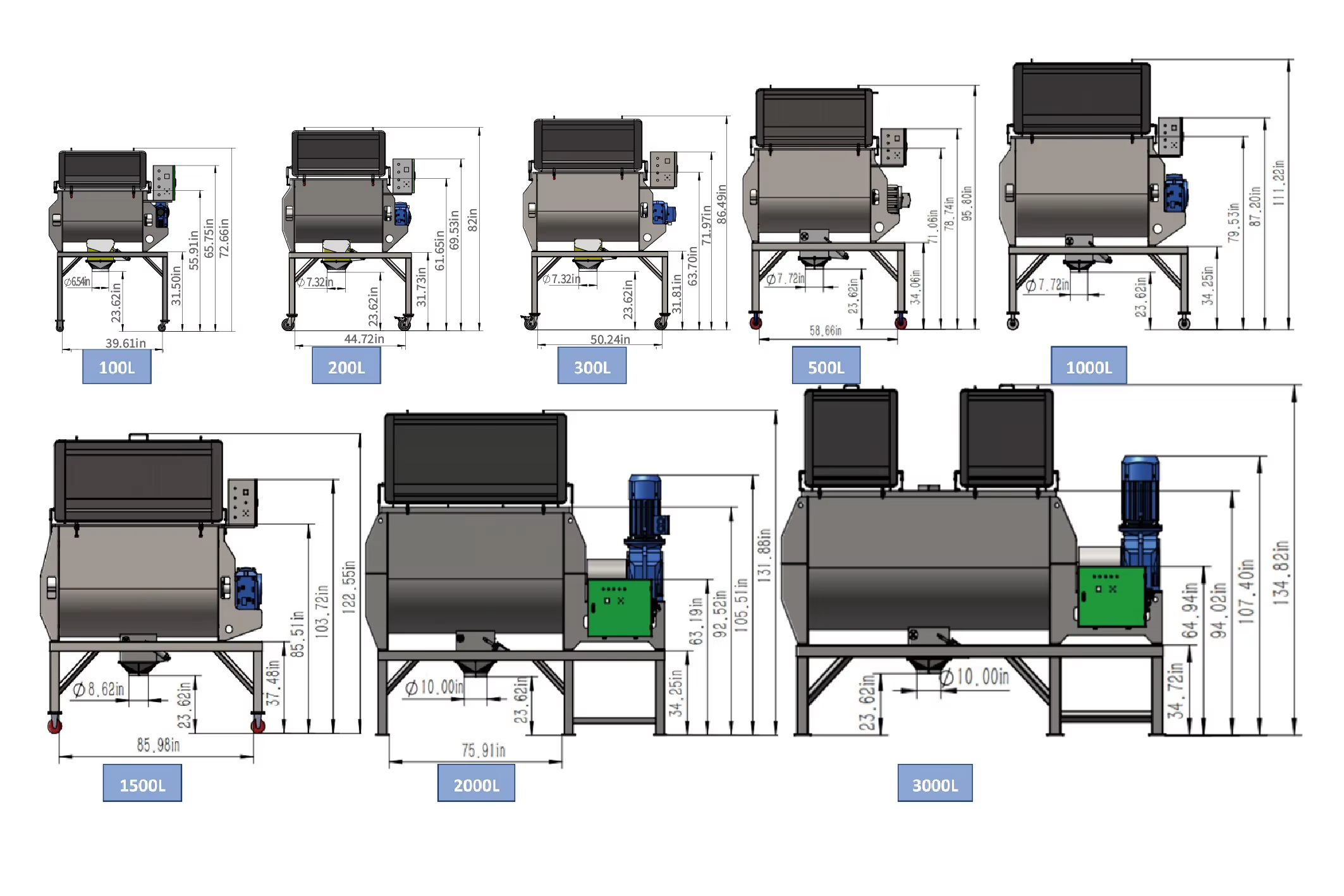

The sizes of ribbon mixers used for mixing spices can vary depending on the scale of production, the type of spices being mixed, and the specific requirements of the application. Here are some typical sizes of ribbon mixers that are commonly used for mixing spices:

Laboratory or pilot scale: Ribbon mixers designed for laboratory or pilot-scale operations typically have a smaller capacity ranging from around 1 liter to 20 liters. These smaller mixers are used for research, development, and small-scale testing of spice blends.

Small to medium scale production: For small to medium-scale spice production, ribbon mixers with capacities ranging from 50 liters to 500 liters are commonly used. These mixers are suitable for producing moderate quantities of spice blends efficiently.

Medium to large scale production: In larger spice production facilities, ribbon mixers with capacities between 500 liters to 2000 liters or more are often utilized. These mixers can handle higher volumes of spices and are suitable for continuous or batch mixing operations.

Custom sizes: Depending on the specific needs of the spice processing industry, ribbon mixers can be custom-built to accommodate even larger capacities, exceeding 2000 liters, to meet the demands of high-volume spice blending operations.

Overall, using a ribbon mixer for blending spices can result in a consistent blend, efficient mixing process, and preservation of the integrity of the spices.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.