Solution feed dry and wet mixer is a special equipment used to mix liquid additives and other feed raw materials. Its main function is to evenly mix liquid additives into solid feed raw materials to ensure the accuracy and uniformity of feed formula. This mixer can efficiently mix liquid additives with solid raw materials through specially designed mixing structure and control system. In the fields of livestock and poultry farming, aquaculture, etc., solution for feed dry and wet mixer plays an important role and provides a reliable mixing solution for feed production.

The working principle of solution for feed dry and wet mixer is based on the rotational motion of the agitator. Liquid additives are evenly sprayed onto solid feed raw materials through nozzles or pipes, and the rotating motion of the agitator fully mixes the liquid additives with the solid raw materials to ensure that each particle is evenly wetted and covered.

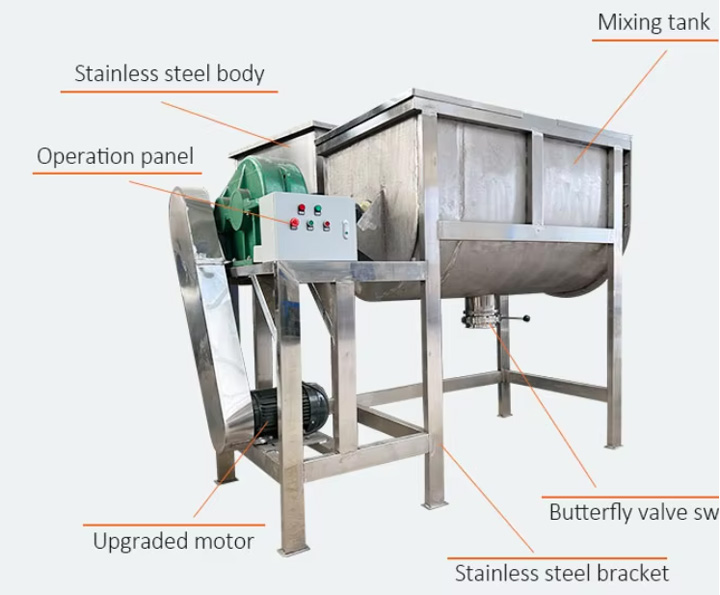

Main structure: usually composed of frame, agitator, motor, control system and other parts.

Agitator: It is the core component of solution for feed dry and wet mixer, which mixes liquid additives and solid feed raw materials through rotational motion.

Motor: drives the agitator to ensure efficient mixing process.

Control system: used to adjust the speed of the agitator, the amount of liquid additives and other parameters to achieve precise mixing control.

Solution for feed dry and wet mixer is widely used in feed production processes that require mixing liquid additives, especially in the following scenarios:

Livestock and poultry farming: Solution for feed dry and wet mixer is used to mix liquid additives such as vitamins and amino acids to improve the nutritional value of feed.

Aquaculture: Solution for feed dry and wet mixer is used to mix various additives in aquatic feed to improve the growth environment of fish and shrimp.

Precise ratio: It can accurately control the amount of liquid additives to ensure the accuracy of feed formula.

Efficient mixing: Through the efficient mixing structure, liquid additives and solid raw materials can be quickly mixed to improve production efficiency.

Save raw materials: Avoid waste of liquid additives and save costs.

Easy operation: Simple operation, easy to control and maintain, and improve production efficiency.

Improve feed quality: Mix evenly to ensure that each feed particle contains an appropriate amount of liquid additives, improve the balance and nutritional value of the feed.

Wide applicability: Not only suitable for feed production, but also for material mixing in other fields, with strong versatility.

Solution for feed dry and wet mixer plays an important role in the field of feed production with its precise mixing ability, high production efficiency and advantages of saving raw materials. Reasonable use and maintenance of the mixer can improve production efficiency, ensure feed quality and meet the nutritional needs of animals.

Through the comprehensive introduction of structure, working principle, application scenarios, characteristics and advantages, I hope you have a deeper understanding of solution for feed dry and wet mixer. If you have any other questions or need further information, please feel free to let me know.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.