Poultry chicken feed mixer is a piece of equipment used for poultry feed production, which uniformly mixes various feed ingredients through a stirring device. This mixer can ensure the balanced distribution of various nutrients in the feed, improve the quality and nutritional value of the feed, and thereby promote the growth and health of poultry. Poultry chicken feed mixer is easy to operate, can save time and labor costs, and improve production efficiency. It is suitable for the poultry breeding industry, including the feed production process of chickens, ducks, geese and other poultry. Through the use of Poultry chicken feed mixer, farmers can produce feed with stable quality and balanced nutrition to meet the growth needs of poultry and improve breeding efficiency.

Poultry chicken feed mixer mixes various feed ingredients through a stirring device. The mixing device usually consists of a stirring paddle or a spiral blade, which mixes the raw materials through high-speed rotation to ensure that the various ingredients are evenly distributed.

Uniform mixing: Poultry chicken feed mixer can evenly mix various feed ingredients to ensure balanced nutrients in each feed.

Save time and manpower: Poultry chicken feed mixer has high working efficiency, saves manpower and time costs, and improves production efficiency.

Precise proportioning: Poultry chicken feed mixer can accurately control the proportion of various raw materials according to formula requirements to ensure the nutritional balance of the feed.

Easy to operate: Poultry chicken feed mixer is simple to operate and easy to master, and does not require complex technical knowledge.

Reduce waste: Through uniform mixing, the waste of feed is reduced and the feed utilization rate is improved.

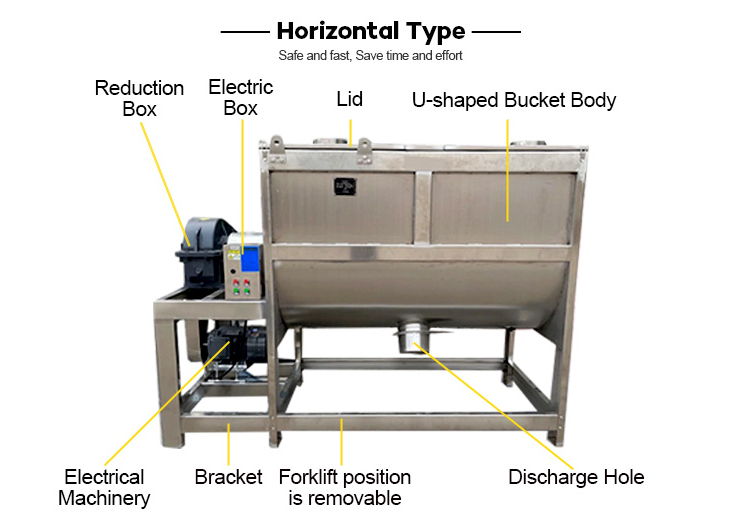

The structure of chicken feed mixer for poultry is simple and usually consists of the following parts

Mixing chamber: It is generally made of stainless steel or high-quality carbon steel, with good corrosion resistance and wear resistance, and can withstand long-term friction and corrosion of feed. The shape of the mixing chamber is usually cylindrical or square, with a smooth interior, which is convenient for the flow and cleaning of feed.

Mixing shaft and blades: The mixing shaft is usually a solid shaft with sufficient strength and rigidity to withstand the torque and impact during the mixing process. The design of the mixing blade is diverse, and the common ones are spiral blades, paddle blades, etc. The spiral blade can effectively promote the axial conveying of the feed, and the paddle blade can enhance the radial mixing effect of the feed. The best mixing effect can be achieved by reasonably combining different types of blades.

Motor and transmission device: The motor is the power source of the chicken feed mixer. Different types of motors can be selected according to the specifications and power requirements of the mixer. The transmission device generally includes belt drive, gear drive or chain drive, etc. Its function is to transmit the power of the motor to the stirring shaft so that the stirring shaft rotates at a suitable speed.

Feed inlet and discharge inlet: The feed inlet is located at the top of the mixing chamber, which is convenient for putting various feed raw materials into the mixing chamber. The discharge inlet is located at the bottom or side of the mixing chamber, and is usually equipped with a valve or discharge device to control the discharge speed and flow of the feed.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Poultry for chicken feed mixer is widely used in poultry farms of various sizes, for example:

Layer farms: used to mix layer feed to improve egg production and egg quality.

Broiler farms: used to mix broiler feed to promote rapid growth of broilers and improve meat quality.

Breeder farms: used to mix breeder feed to ensure the health of breeders and improve fertilization and hatching rate

Ensure balanced feed nutrition: Chickens need a variety of nutrients for growth, including protein, carbohydrates, vitamins, minerals, etc.

Improve feed utilization: Evenly mixed feed can be better digested and absorbed by chickens, reducing feed waste.

Easy to add additives: In chicken feed, some additives are often needed, such as drugs, vitamin premixes, amino acids, etc. Through the chicken feed mixer, these additives can be evenly mixed into the feed to ensure that each chicken can get the right amount of additives, so as to achieve the purpose of preventing diseases and promoting growth.

With the development of technology, poultry chicken feed mixer is also constantly innovating and upgrading. Some mixers are equipped with advanced automatic control systems, which can achieve more precise mixing and proportioning, improving production efficiency and product quality.

Overall, poultry chicken feed mixer plays an important role in poultry farming, providing reliable technical support for poultry feed production through its efficient mixing capacity and precise proportioning. We can provide animal feed capacity with a one-time mixing volume of 100-6000 kg, and choose the equipment model that suits you according to your needs. We pack all machines into containers at our factory to ensure safe transportation. If you are interested in our equipment, welcome to inquire.

As the source manufacturer of poultry chicken feed mixer. Our product price range is wide, fully considering the needs and budgets of farmers of different sizes. For small farmers, we have launched a series of affordable entry-level products. For medium-sized farms, we provide mixers with a capacity of 500-1500 kg. For large-scale breeding enterprises, our large chicken feed mixers have a capacity of more than 1500 kg. The prices of different models are also different, and the final price will be quoted in combination with your needs!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.