As a major agricultural country, Bangladesh has a rapidly developing poultry farming industry, and feed production is an important part of its livestock and poultry farming industry. In this process, chicken feed mixers play a key role, helping farmers mix various feed raw materials, providing balanced and nutritious feed, and promoting the healthy growth of poultry. Chicken feed mixers are a type of equipment used for poultry feed production, and their main function is to evenly mix various feed raw materials. This machine usually includes components such as a mixing barrel, a stirrer or a spiral stirrer.

Bangladesh chicken feed mixers shear, tumble and mix various feed raw materials in a mixing barrel through the rotation of a stirrer or a spiral stirrer to achieve uniform distribution of various ingredients in the feed. The operation of the stirrer causes granular and powdered feed raw materials to tumble and shear continuously in the mixing barrel, thereby achieving mixing. The internal design of the mixer is reasonable to ensure that the feed raw materials are fully mixed in the mixing barrel, so that various nutrients in the feed are evenly distributed, and the quality and nutritional value of the feed are improved.

Bangladesh chicken feed mixers are widely used in poultry feed manufacturers, farms and other scenarios. In the poultry farming industry, feed quality directly affects the growth and health of poultry. Chicken feed mixers can evenly mix various feed raw materials to ensure a balanced distribution of various nutrients in the feed. Through the efficient mixing function of the mixer, manufacturers can produce stable quality and nutritious chicken feed to meet the growth needs of poultry. Whether it is a large farm or a small poultry farmer, chicken feed mixers are important equipment to improve production efficiency and ensure feed quality.

Uniform mixing: Ensure that various feed raw materials are fully mixed to improve the quality and nutritional value of the feed.

Efficient and saving: The mixing process is efficient and fast, saving time and labor costs, and improving production efficiency.

Easy to operate: The operation is convenient, and the mixing time and speed can be adjusted as needed, which is suitable for feed production with different formulas.

Stable quality: Keep the feed quality stable to meet the needs of poultry.

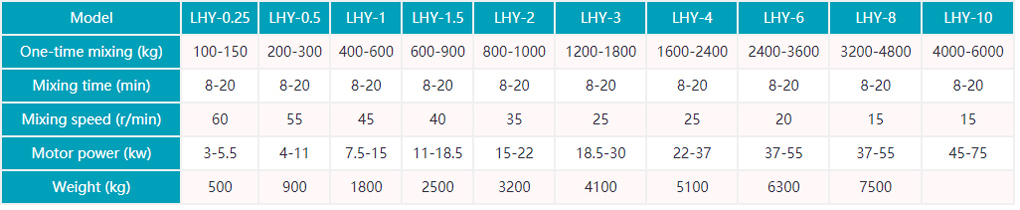

The mixing uniformity depends on factors such as the specific mixer model, design features, operation mode and mixing time. The mixing rate of the chicken feed mixer produced by Dahan can reach 99%. The design of the mixer allows the feed raw materials to be fully mixed to ensure a balanced distribution of nutrients. The mixing time depends on the type and proportion of feed ingredients, usually between 8 minutes and 20 minutes, to ensure uniform mixing.

In the chicken feed production in Bangladesh, feed mixer is one of the indispensable equipment. Its efficient mixing function and convenient operation characteristics help farmers improve production efficiency, produce high-quality feed, and promote the development of poultry farming in Bangladesh.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.