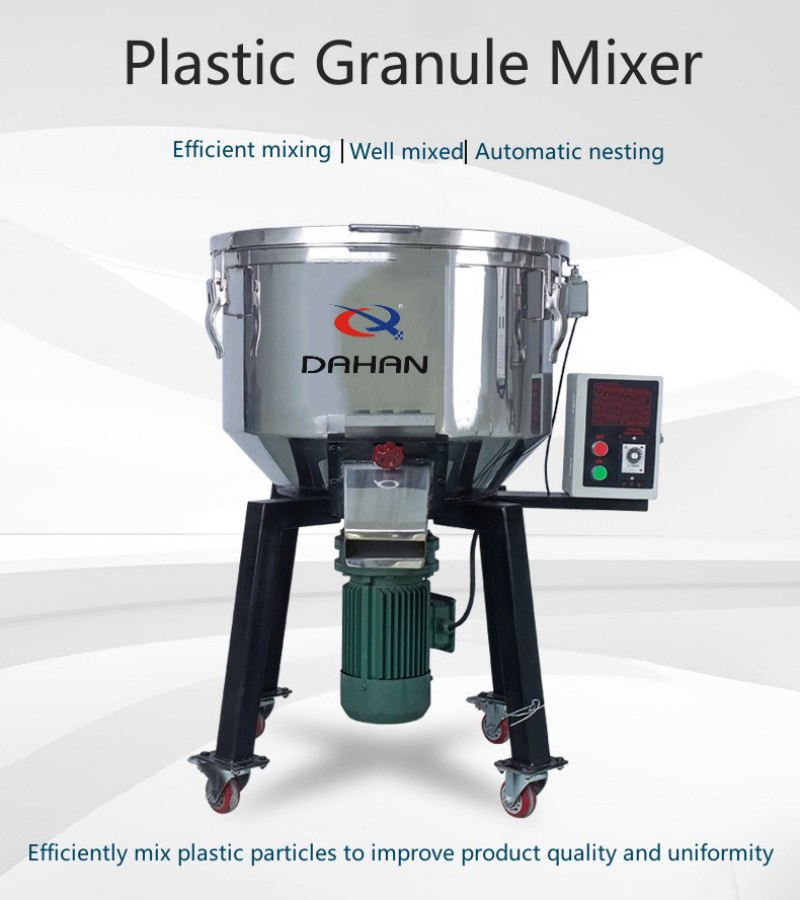

Efficiently mix plastic particles to improve product quality and uniformity

![]()

![]()

Price:$300.00-$1,500.00/Set

Consult now and enjoy a 10% discount

Capacity: 50L-500L

Output (kg/h): 25 - 3000 kg/h

Power: 1.5kw-11kw

Application: Plastic particles: including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyester (PET), polycarbonate (PC), polyamide (PA), etc.

Rubber particles: natural rubber particles, styrene-butadiene rubber particles, nitrile rubber particles, etc.

Chemical raw materials: pigments, dyes, additives, catalysts, etc.

Powdered materials: fly ash, carbon black, metal powder, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Plastic granule mixer is a device specially used to mix plastic granules of different types and colors. It mixes the plastic particles thoroughly by stirring, turning or rotating to achieve even distribution among the particles. This kind of equipment has a simple structure and is easy to operate. It can improve the quality and consistency of plastic products and is widely used in the plastic processing industry.

The main function of the plastic granule mixer is to mix plastic granules of different types and colors to achieve uniform distribution among the granules and improve the mixing quality. It can effectively eliminate the stratification phenomenon between particles, avoid the aggregation and accumulation of particles, and ensure the quality and appearance consistency of plastic products. This kind of equipment usually consists of a mixer, rotor, motor, etc. It is simple to operate and suitable for plastic processing enterprises of all sizes. By using plastic granule mixers, companies can improve production efficiency, reduce waste generation, and enhance the market competitiveness of their products.

Plastic granule mixer is widely used in the plastic processing industry. Its main uses include:

Plastic product production: plastic granule mixer is used to mix plastic granules of different types and colors to prepare a uniform mixture. This mixture can be used to make a variety of plastic products, such as plastic containers, pipes, films, injection molded parts, etc. Through the use of mixers, the quality and consistency of the product can be improved.

Plastic recycling:In the plastic recycling process, plastic particles of different types and sources need to be mixed to prepare recycled plastic that meets the requirements. The plastic granule mixer can thoroughly mix the recycled plastic granules so that they have uniform properties and chemical composition so that they can be used again in the production of plastic products.

Plastic color matching:plastic granule mixer can also be used in the color matching process of plastic granules. By mixing plastic particles of different colors, the desired colors and effects can be obtained. This is very important when manufacturing colored plastics or special effects plastics.

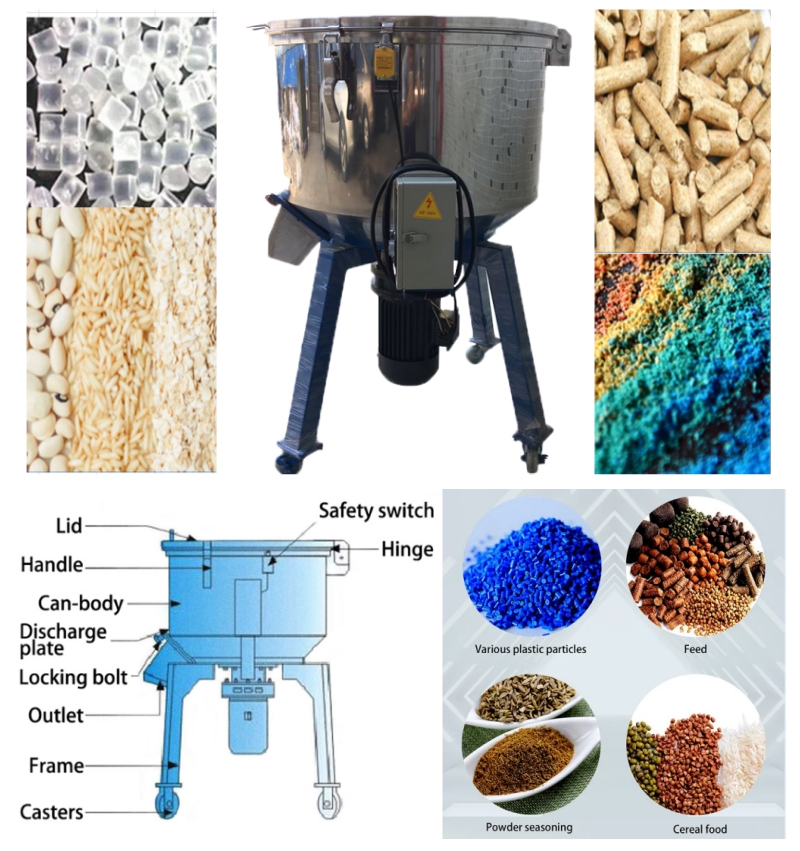

Plastic granule mixers can mix various types of granular materials, not just plastic. Here are some common material types:

Plastic particles: Plastic particles of various types and colors, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyester (PET), polycarbonate (PC) ), polyamide (PA), etc.

Rubber particles: different types of rubber particles, such as natural rubber particles, styrene-butadiene rubber particles, nitrile rubber particles, etc.

Chemical raw materials: granular chemical raw materials, such as pigments, dyes, additives, catalysts, etc.

Powdered materials: Some powdered materials can also be mixed through a particle mixer, such as fly ash, carbon black, metal powder, etc.

Food pellets: In the food processing industry, pellet mixers can also be used to mix food pellets, such as cereals, beans, dried fruits, etc.

The working principle of plastic granule mixer mainly includes the following steps:

Adding materials: First, add the plastic particles of different types and colors to be mixed into the hopper of the mixer according to a certain proportion. The dosing process can be done manually or automatically.

Mixing: Once the plastic pellets are added to the mixer, the mixer activates a stirrer, rotor or other mixing device to stir, turn or rotate the pellets. This allows the plastic particles to be fully mixed and achieve an even distribution between particles.

Time control: The mixing time can be adjusted as needed to ensure that the particles are fully mixed. Too long a time may result in overmixing, and too short a time may result in uneven mixing.

Temperature control (optional): In some cases, plastic pellets need to be heated or cooled to change their physical properties or improve mixing effects. Mixers usually have temperature controls that can be adjusted as needed.

Discharge: After mixing is completed, the mixed plastic particles can be taken out through the discharge port. Unloading can be done manually or automatically, depending on the design and operation of the mixer.

Improve product quality

The plastic granule mixer can fully mix plastic granules of different types and colors to ensure even distribution among the granules. This improves the quality and consistency of your products and avoids problems with color differences or unevenness.

Reduce waste generation

Through precise control of the mixer, waste generation caused by uneven mixing can be avoided. The mixer can fully mix different types of plastic particles to maximize the utilization of raw materials and reduce the waste of waste materials.

Increase production efficiency

Using plastic granule mixer can automate the mixing process and improve production efficiency. Compared with manual mixing, the mixer can complete the mixing task more quickly, saving labor and time costs.

Achieve specific color requirements

plastic granule mixer can be used in the color matching process of plastic granules. By mixing particles of different colors, the desired colors and effects can be obtained to meet specific color requirements.

Wide range of application

plastic granule mixer is suitable for various types of plastic granules, including plastics of different types and origins. Whether it is raw material production or recycling, mixers can do it all.

Easy to operate

plastic granule mixers usually have simple and easy-to-understand operating interfaces and control systems, making them easy to operate. The operator only needs to set the mixing parameters and start the mixer to complete the mixing process without complex operating skills.

| Model | Capacity(kg) | Power(kw) | Quickness | Weight(kg) |

| L-50 | 50 | 1.5 | 63 | 90 |

| L-100 | 100 | 3 | 63 | 126 |

| L-150 | 150 | 4 | 63 | 163 |

| L-200 | 200 | 5.5 | 63 | 228 |

| L-300 | 300 | 7.5 | 63 | 262 |

| L-500 | 500 | 11 | 63 | 460 |

A plastic products manufacturing company uses an advanced plastic granule mixer on its production line to improve product quality and production efficiency. The company produces various types of plastic products that require mixing different types and colors of plastic pellets to achieve consistent color and quality.

After the introduction of the mixer, the company's production efficiency increased significantly. The mixer's automated operation and efficient mixing capabilities make the mixing process faster and more precise. No longer need to rely on manual mixing, saving a lot of time and labor costs. At the same time, the precise control and uniform mixing characteristics of the mixer significantly improve the quality of the product. There is no longer any problem of color difference or unevenness, and the appearance and performance of the product are more stable and reliable.

Xinxiang Dahan plastic granule mixer manufacturer is a company specializing in manufacturing vibration equipment and one of the plastic granule mixer manufacturers. The company has many years of industry experience and advanced production technology, and is committed to providing high-quality, reliable and efficient products. The plastic granule mixer adopts high-quality materials and precision processing technology, with stable performance and long life. This product has reasonable design, easy operation and excellent mixing effect. Xinxiang Dahan plastic granule mixer has won wide recognition from customers for its excellent manufacturing capabilities and good after-sales service. Is one of the trustworthy plastic granule mixer manufacturers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.