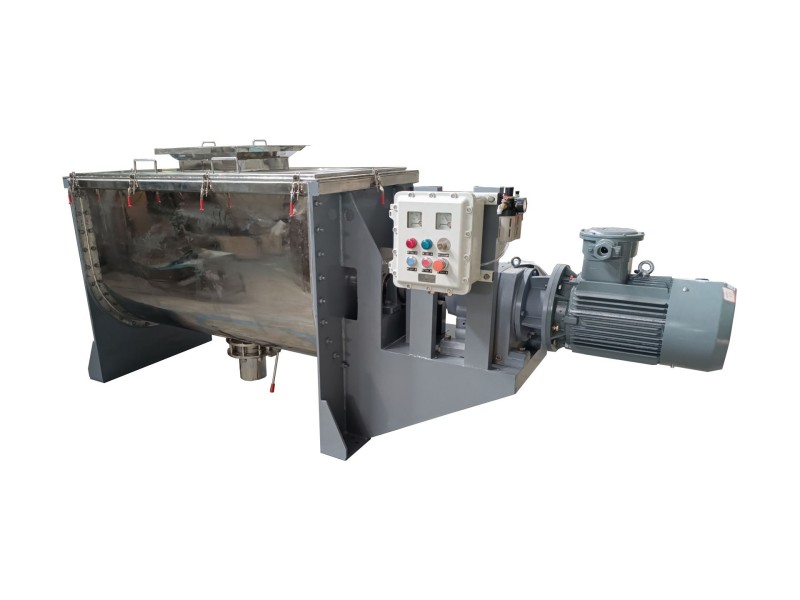

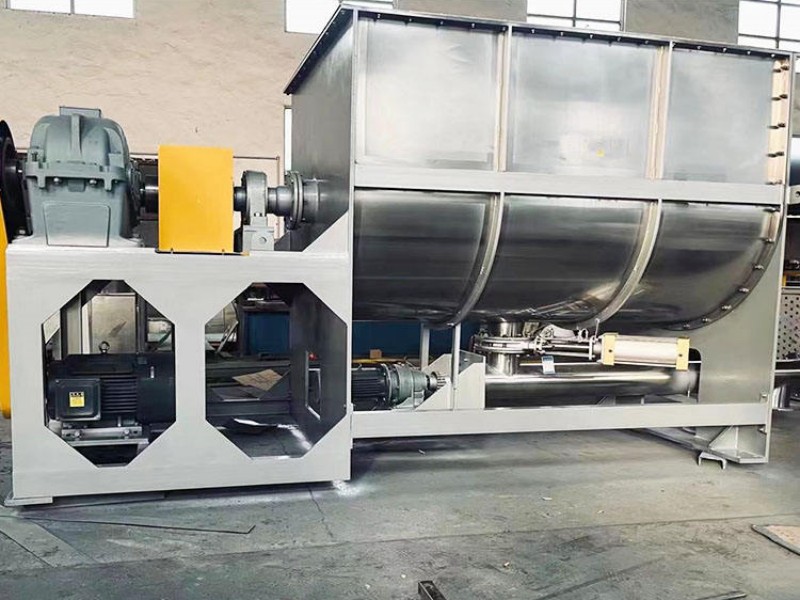

Horizontal food additive mixer is a special equipment used for additive mixing and preparation processes in the food industry. Its main function is to uniformly mix different food additives to ensure the quality and taste of food products. The horizontal food additive mixer consists of a horizontal cylindrical container and a rotating agitator. The stirrer pushes the food additives to one side of the container through a rotating motion, and then lifts it from one side of the container to the other side of the container to achieve even distribution and mixing of the additives.

The working principle of the horizontal food additive mixer is to mix food additives through the rotation of the agitator. Usually, it consists of a horizontally placed cylindrical container and a rotating agitator. The agitator can be spiral, paddle-shaped or other shapes. Choose the appropriate agitator according to different mixing tasks.

When the horizontal food additive mixer starts working, the food additives are put into the container. The agitator begins to rotate, pushing the additive to one side of the container and then lifting it from one side of the container to the other. This process is repeated continuously so that the additives are fully stirred and mixed in the container. Due to the rotating motion of the mixer, the additives are continuously thrown up and down, thereby achieving even distribution of the additives.

Horizontal food additive mixers have a wide range of application scenarios in the food industry. It can be used for mixing food ingredients, such as flour, powdered sugar, yeast, spices, etc.

In the preparation process of baked goods such as bread, cakes, and biscuits, the horizontal food additive mixer can mix different additives to ensure the uniformity and stability of the product.

In the preparation of condiments and sauces, the horizontal food additive mixer can mix different condiments to achieve the taste and flavor of the product.

Horizontal food additive mixers have many advantages that make them widely used in the food industry.

Efficient mixing: Due to the rotating motion of the mixer, the food additives are fully stirred and mixed in the container, ensuring that various additives can be evenly distributed throughout the mixing process, improving the quality and taste of the product.

Large capacity and production capacity: The horizontal placement design of the horizontal food additive mixer makes the mixing container have a relatively large capacity and can accommodate a large amount of additives for mixing. It is suitable for large-scale production and batch production needs, and improves production efficiency.

Flexible and adjustable: The rotation speed and mixing time of the mixer can be adjusted according to different additives and formula requirements, and the operator can perform precise control according to actual needs to achieve the best mixing effect.

Xinxiang Dahan is a well-known food equipment manufacturer that also provides horizontal food additive mixers. The horizontal food additive mixers produced are manufactured using advanced technology and high-quality materials, and are reliable and durable. These equipment can efficiently mix food additives evenly to ensure product quality and taste. Xinxiang Dahan's horizontal food additive mixer has the characteristics of large capacity and flexible adjustment, and is suitable for various additive mixing needs in the food industry.

To sum up, the horizontal food additive mixer uniformly mixes food additives through the rotating motion of the agitator and is widely used in the additive mixing and preparation processes in the food industry. It has the advantages of efficient mixing, large capacity, flexible adjustment, etc., and is provided by some well-known manufacturers. These equipment play an important role in the food industry, improving the quality and production efficiency of food products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.