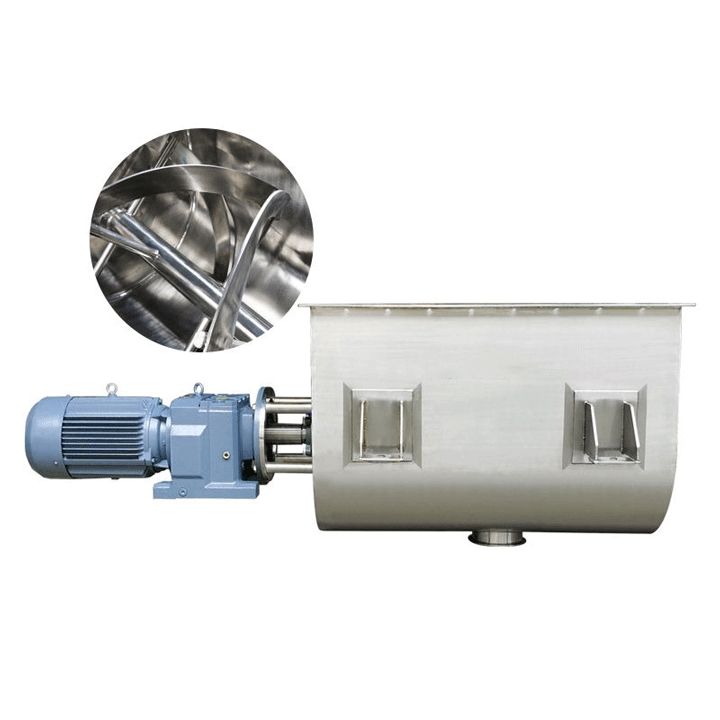

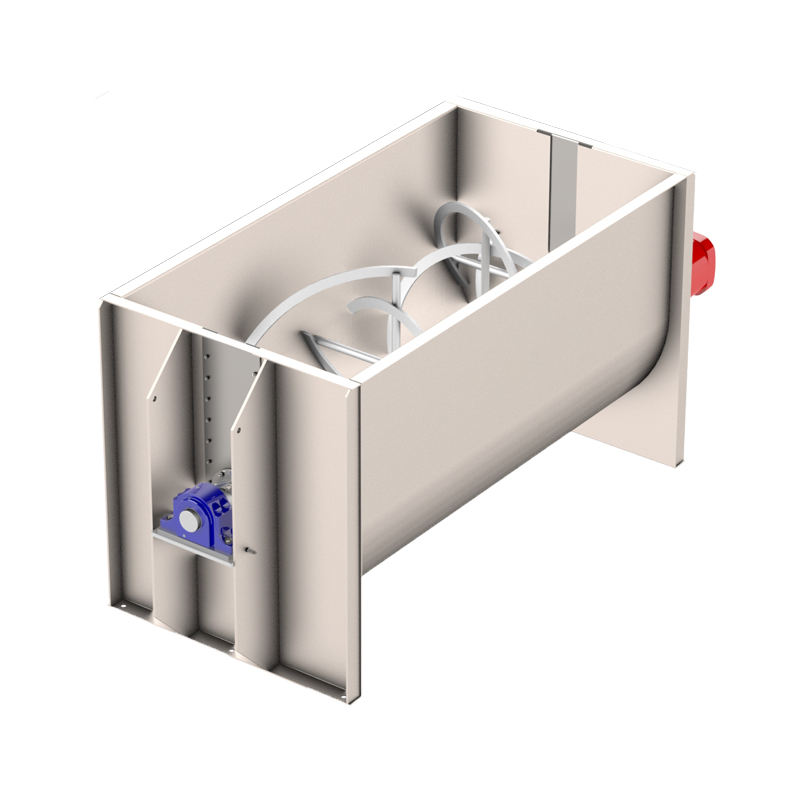

Single shaft horizontal mixer is a common mixing equipment, mainly used to uniformly mix solid materials of different particle sizes and properties. This model usually consists of a horizontally placed main shaft and a mixing paddle rotating around the main shaft. Through the rotation of the mixing paddle, the materials are pushed, thrown up and dropped in the mixer tank, resulting in shearing, convection and turbulence effects, thereby achieving uniform mixing of the materials. Single shaft horizontal mixers are widely used in chemical, food, pharmaceutical and other industries for mixing operations during the production process to ensure the quality and consistency of the final product.

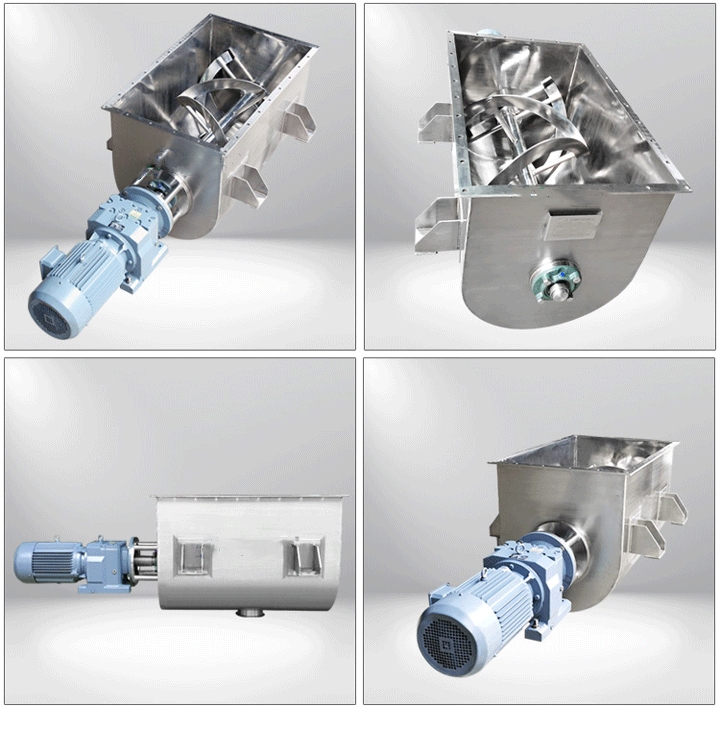

The working principle of a single shaft horizontal mixer is based on the rotating motion of the mixing paddle. During operation, solid materials are placed in the tank of the mixer, and then the mixer is started. The main shaft drives the mixing paddle to rotate, pushing the material from the bottom to the top, and then evenly throwing it back to the bottom from the top. This pushing, pulling and throwing movement produces shear, convection and turbulence effects, allowing the materials to be fully mixed. During the mixing process, the particles of the material rub and collide with each other, thereby achieving mixing and dispersion between the particles.

Single shaft horizontal mixers are widely used in pharmaceutical, chemical, food, building materials and other fields. In the pharmaceutical industry, it is often used to mix pharmaceutical powders, preparations, etc.; in the chemical industry, it is used to mix chemical raw materials; in the food industry, it is used to mix food additives, seasonings, etc.; in the building materials field, it is used to mix cement, lime and other raw materials .

The main function of a single shaft horizontal mixer is to mix two or more solid materials to achieve uniform distribution. It can effectively mix granular or powdery materials, including but not limited to chemical raw materials, food additives, pharmaceutical raw materials, agricultural fertilizers, etc. By mixing, these materials can achieve a certain consistency, ensuring the quality of the final product.

Simple structure: The single shaft horizontal mixer consists of a main shaft and a mixing paddle. The structure is relatively simple and easy to operate and maintain.

Uniform mixing: The rotation of the mixing paddle can effectively push, throw and drop the materials, producing cutting, convection and turbulence effects, thereby achieving uniform mixing.

Strong adaptability: The single shaft horizontal mixer is suitable for mixing a variety of solid materials with different properties and particle sizes, and has a wide range of applications.

High mixing efficiency: The design and rotation mode of the mixing paddle ensure high mixing efficiency, shorten the mixing time, and improve production efficiency.

Easy operation: The operation of the equipment is relatively simple. You usually only need to put the materials into the mixer, set the mixing time and speed, and then start the machine.

High reliability: Single shaft horizontal mixers are usually made of high-quality materials, with stable performance and long service life.

In order to obtain better mixing effect, the operator can set the mixing time and the rotation speed of the mixing paddle as needed. The length of mixing time and the speed of rotation will affect the uniformity and speed of mixing.

The single shaft horizontal mixer is a commonly used mixing equipment that uniformly mixes solid materials of different properties and particle sizes through a rotating mixing paddle. Its structure is simple, easy to operate, and has high mixing efficiency and reliability. It is widely used in chemical, food, pharmaceutical and other industries, providing an effective solution to the mixing needs in the production process. If you want to know more about our products, you can go to our product page to view them.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.