In modern industrial production, in order to improve production efficiency, ensure product quality and reduce costs, all walks of life are constantly seeking efficient mixing equipment. Among them, the ribbon mixer plays an important role as a widely used mixing equipment. The following is a detailed introduction to the definition and working principle of the ribbon mixer.

What is a ribbon mixer?

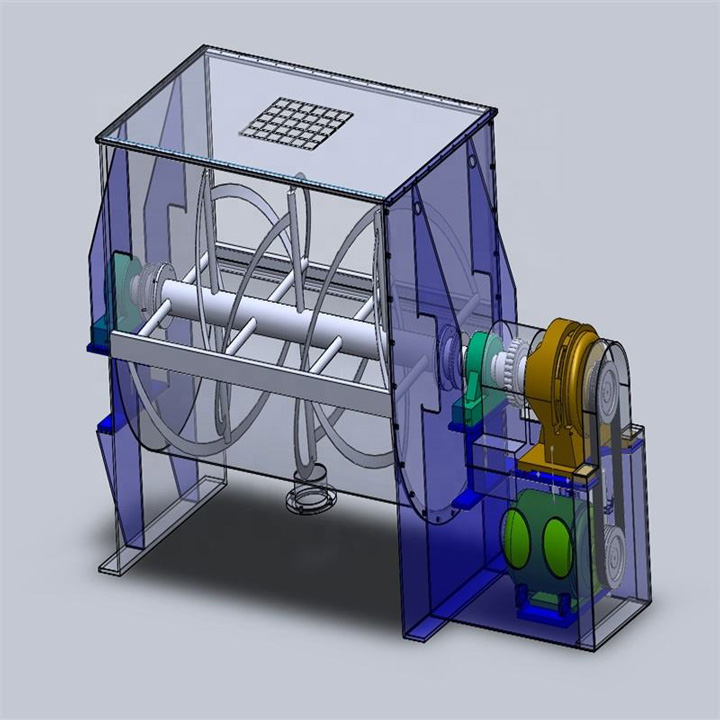

Ribbon mixer is a commonly used industrial mixing equipment used to mix different granular or powdery raw materials. Its working principle is based on the rotation of the spiral blades on the spiral shaft, mixing the raw materials through forced convection to ensure the uniformity and quality of the mixed materials. Ribbon mixers usually consist of a host machine, a transmission device, a feed port, a discharge port, and an electrical control system. The main unit contains spiral blades, and the shape and arrangement of the blades will affect the mixing effect.

What are the features and advantages of ribbon mixers?

Efficient mixing: The ribbon mixer can mix raw materials quickly and evenly, improving production efficiency.

Wide applicability: widely used in food, chemical, pharmaceutical, agriculture, environmental protection and other industries for mixing various granular or powdery raw materials.

Various forms: According to different process requirements, different forms of ribbon mixers such as internal stirring blades with scrapers and spray gun devices can be selected.

Easy to clean and maintain: Simple structure and convenient cleaning, which reduces maintenance costs during the production process.

What are the application areas of ribbon mixers?

Food industry: used to mix flour, seasonings, granules and other food raw materials to prepare bread, pastries, biscuits and other food products.

Chemical industry: used for mixing chemical raw materials to prepare coatings, adhesives, cosmetics and other products.

Pharmaceutical industry: used to mix pharmaceutical raw materials and prepare tablets, capsules, oral liquids and other drugs.

Agricultural field: used to mix feed raw materials, prepare livestock and poultry feed, and improve the nutritional balance of feed.

Environmental protection industry: used to mix waste materials and solid waste for resource utilization or treatment to reduce environmental pollution.

Raw material feeding: Add the raw materials to be mixed into the ribbon mixer through the feeding port.

Spiral blade mixing: Start the ribbon mixer, and the spiral blades start to rotate, pushing the raw materials along the direction of the spiral axis. The rotation of the blades causes forced convection of the raw materials around the spiral shaft to achieve mixing.

Uniform mixing: In the ribbon mixer, the raw materials are continuously stirred and turned over to achieve uniform mixing of the raw materials in each part.

Discharge: After mixing is completed, the mixed materials are taken out from the discharge port for subsequent production processes.

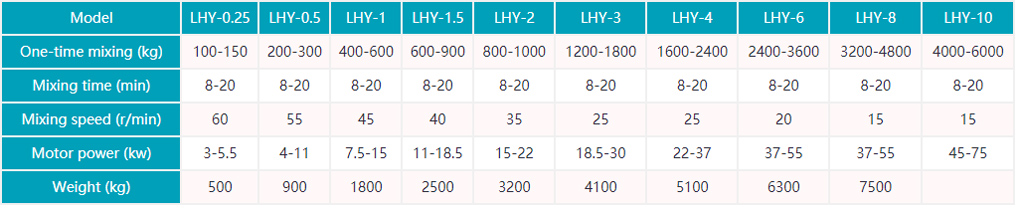

In short, ribbon mixers play an important role in various industries, improving the accuracy and efficiency of the production process, ensuring product quality, and meeting the needs of different industries for mixing processes. Through continuous technological innovation and application promotion, ribbon mixers will continue to play an important role in industrial production. Dahan manufacturers produce ribbon mixers in various models, with short mixing time and high mixing efficiency. If you want to know more about ribbon mixers, please click on our product page to browse.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.