Horizontal mixers are suitable for mixing various powdery, granular and fibrous materials, including chemical industry, metallurgy, building materials, food, medicine and other industries. It has the characteristics of good mixing effect, easy operation, short mixing time and high mixing uniformity, and can meet the mixing needs of different industries.

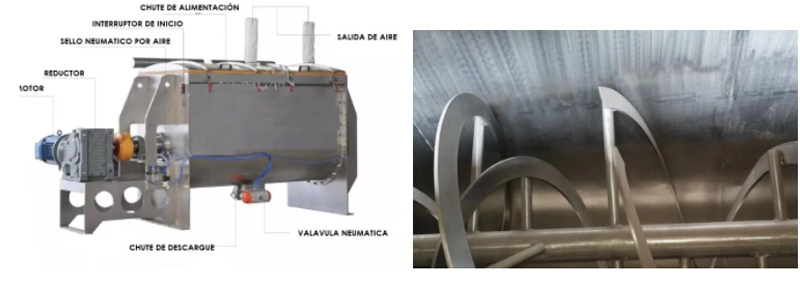

Horizontal mixers usually consist of a frame, mixing barrel, mixing device, transmission device, feed port, discharge port and other parts. The overall structure is compact and occupies a small area, making it suitable for use in limited spaces. The mixing barrel is usually cylindrical in shape, and the mixing device includes a mixing blade or a stirrer. The feed raw materials are mixed through the rotation of the mixing device.

Horizontal mixer is easy to operate

The operation of the horizontal mixer is relatively simple. Generally, you only need to control the start button to start the mixer. Operators only need to perform simple operations to complete the mixing task, without complex operating procedures or professional skills, which reduces the difficulty of operation.

The horizontal mixer fully mixes the feed raw materials through the stirring device to ensure that various raw materials are evenly distributed throughout the mixing barrel. The mixing blades or stirrers in the mixing barrel can effectively stir and turn the raw material particles so that various raw materials are fully contacted and mixed, thereby improving the mixing effect and ensuring the uniformity and stability of the feed.

The horizontal mixer is suitable for a variety of granular, powdery or granular and powdery mixed feed raw materials, such as feed pellets, corn flour, soybean meal, etc. At the same time, it can also be used to mix other granular or powdery raw materials, such as fertilizers, chemical raw materials, etc. This wide range of application makes horizontal mixers widely used in agriculture, feed processing and other fields.

The horizontal mixer has high mixing efficiency and can quickly mix various feed ingredients to improve production efficiency. The stirring device in the mixer continuously stirs and turns the raw material particles through rotational motion, which accelerates the mixing speed, makes the mixing effect more uniform, and saves time and labor costs.

Horizontal mixer has good mixing uniformity

Since the horizontal mixer uses a stirring device to mix the raw materials, it can ensure that the feed raw materials are fully mixed and evenly distributed. The mixed feed has high uniformity, and various nutrients are evenly distributed throughout the mixture, ensuring that animals receive balanced nutrition and promoting the growth and development of animals.

As a commonly used mixing equipment, horizontal mixers play an important role in agriculture, feed processing and other fields. Its features include compact structure, easy operation, good mixing effect, wide application range, high mixing efficiency and good mixing uniformity. Through the use of horizontal mixers, feed can be improved. The quality and nutritional balance provide important support for production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.