Vitamins and minerals for horizontal mixer is a device for mixing vitamins and minerals. Through the synergistic action of a horizontally rotating drum and helical ribbon blades, it achieves rapid and uniform mixing of trace ingredients such as vitamins and minerals with a carrier. Customizable drum dimensions, blade configuration, and drive power are adjustable to meet specific production needs, from laboratory trials to industrial scale production. Material options include 304 stainless steel, 316L medical-grade stainless steel, and carbon steel lined with polyethylene, meeting specific requirements for corrosion resistance and metal contamination prevention. A single mixing cycle takes only 7-15 minutes, with a capacity range of 50kg to 10 tons, supporting continuous operation. An optional CIP flushing system utilizes high-pressure sprays and rotating brushes for comprehensive cleaning, reducing refill cleaning time to under 30 minutes.

Based on customer production needs, we offer vitamins and minerals Horizontal Mixer primarily in stainless steel and carbon steel. These differing material properties make them suitable for different applications.

Stainless steel mixers: Core contact components are made of 304 or 316 stainless steel, offering excellent corrosion resistance, rust resistance, and easy cleaning. This prevents metal ion contamination of active ingredients like vitamins and minerals, meeting the high cleanliness standards of industries like food, pharmaceuticals, and infant food.

Carbon steel mixers: Utilizing high-quality carbon steel as the base material, they are often painted or galvanized. These mixers are relatively cost-effective, offer high structural strength, and possess a strong load-bearing capacity. However, their corrosion resistance is weaker and they are easily affected by moisture or acidic or alkaline materials. They are therefore more suitable for applications such as feed and chemical industries, where cleanliness requirements are lower and materials are not particularly corrosive.

The Vitamins and minerals for horizontal mixer has significant core advantages. Its twin-ribbon agitator creates strong convection, achieving mixing uniformity exceeding 99%, ensuring precise dispersion of trace ingredients. It supports customization from 500L to 5000L, adapting to different production capacities.

Three-dimensional compound motion: Through the convection circulation of the double-layer propellers and the barrel-lifting design, trace ingredients such as vitamins and minerals are sheared and diffused in three dimensions, achieving a uniformity of D90 ≤ 0.5% in 7-15 minutes.

Flexible material selection: Available in 304 stainless steel, 316L medical-grade stainless steel, and carbon steel lined with polyethylene, it meets the hygiene and corrosion resistance requirements of various industries, including food, pharmaceuticals, chemicals, and feed.

Customizable structural design: The barrel size, propeller angle, and discharge method can be adjusted according to material characteristics. It also supports special process requirements such as vacuum loading and low-temperature mixing.

Large-capacity mixing: Single-shot mixing capacity ranges from 50 kg to 10 tons, supporting small-batch trial runs to large-scale continuous production, reducing material changeover frequency and increasing production capacity.

Fully enclosed structure: Prevents dust leakage and cross-contamination, meeting the cleanroom requirements of the food and pharmaceutical industries.

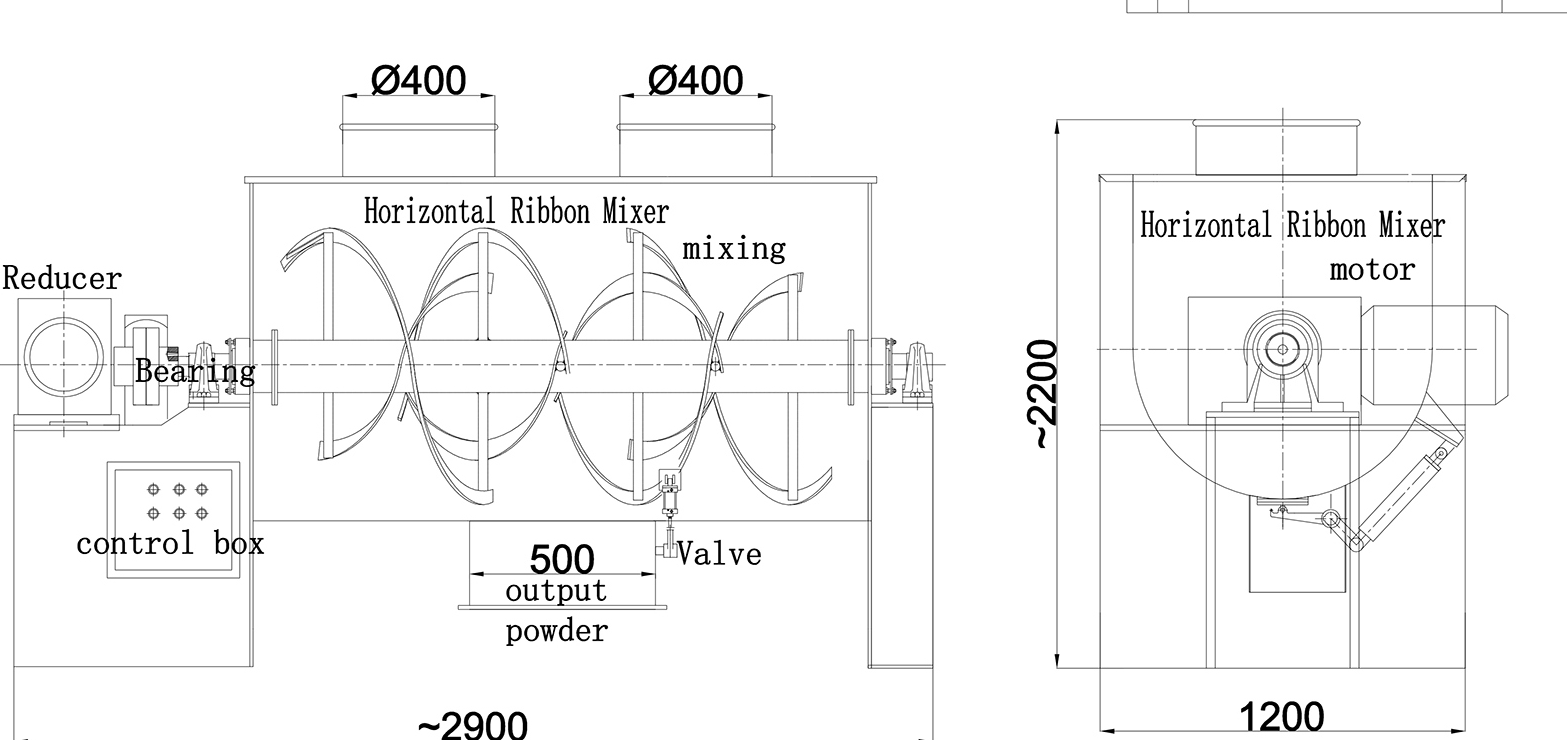

Vitamins and minerals for horizontal mixer utilizes a horizontal cylindrical structure with built-in double or multiple layers of spiral ribbon impellers. During operation, a motor drives the main shaft, which in turn rotates the propellers. The outer spiral ribbon pushes the material from the ends of the cylinder toward the center, while the inner spiral ribbon moves in the opposite direction, pushing the material back from the center to the ends, creating a convection circulation. This two-way, compound motion causes intense shearing, diffusion, and tumbling of raw materials, such as vitamin powder and mineral particles, in three dimensions, ensuring uniform coating of the microscopic components with the carrier.

The horizontal mixer for vitamins and minerals is based on a horizontally positioned mixing drum, equipped with twin or multi-layered S-shaped ribbon blades. This propulsion system uses a combination of spiral propulsion and three-dimensional motion to ensure uniform mixing of fine-particle materials such as vitamins and minerals.

Mixing Chamber:It utilizes a horizontal U-shaped or trough-shaped design. The material-contacting areas are primarily constructed of 304/316 stainless steel, resulting in a smooth interior with no dead corners, minimizing material carryover and contamination. The chamber volume can be customized.

Mixing System:The core is a twin-ribbon mixing shaft consisting of two layers of ribbons. The outer ribbon propels the material toward the center, while the inner ribbon reverses the direction, pushing the material to the sides, creating a forced convection circulation system.

Drive System:Comprising a motor, reducer, and coupling, it provides power to the mixing shaft. It supports variable frequency drive, allowing the speed to be adjusted according to the material's characteristics.

Feed Inlet:Located at the top of the chamber, it can be used with a feeding station or conveyor for automatic feeding.

Discharge port: Located at the bottom or side of the chamber, equipped with a pneumatic or manual valve to control the discharge rate.

Our vitamins and minerals for horizontal mixers have a wide range of applications, primarily covering industries with high requirements for mixing uniformity, hygiene standards, and ingredient stability.

In the food and nutritional supplement industry: Vitamin and mineral mixing is widely used in solid beverages, compressed candies, and functional foods. During production, vitamin premix powders and mineral complexes such as calcium, iron, and zinc must be mixed with carriers such as powdered sugar and starch to ensure accurate dosage per tablet or packet.

In the pharmaceutical and health product industry: Vitamin and mineral mixing is a critical step in tablet, capsule, and granule production. During tablet or capsule filling, the vitamin and mineral complex powder must be mixed with excipients such as microcrystalline cellulose and magnesium stearate to ensure a uniform active ingredient content that meets pharmacopoeial standards.

In the feed and pet food industry: Vitamin and mineral mixing enhances product nutritional quality. During premix production, vitamins A, D3, and E, as well as mineral premixes such as copper, iron, and manganese, required for livestock and poultry feed, are combined to improve animal nutrient absorption.

Chemical and New Materials Industries: Mostly used in the preparation of catalyst supports and ceramic pigments. When making catalyst supports, active metal oxides such as zinc oxide and iron oxide must be mixed with the support material to produce highly dispersed catalysts.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

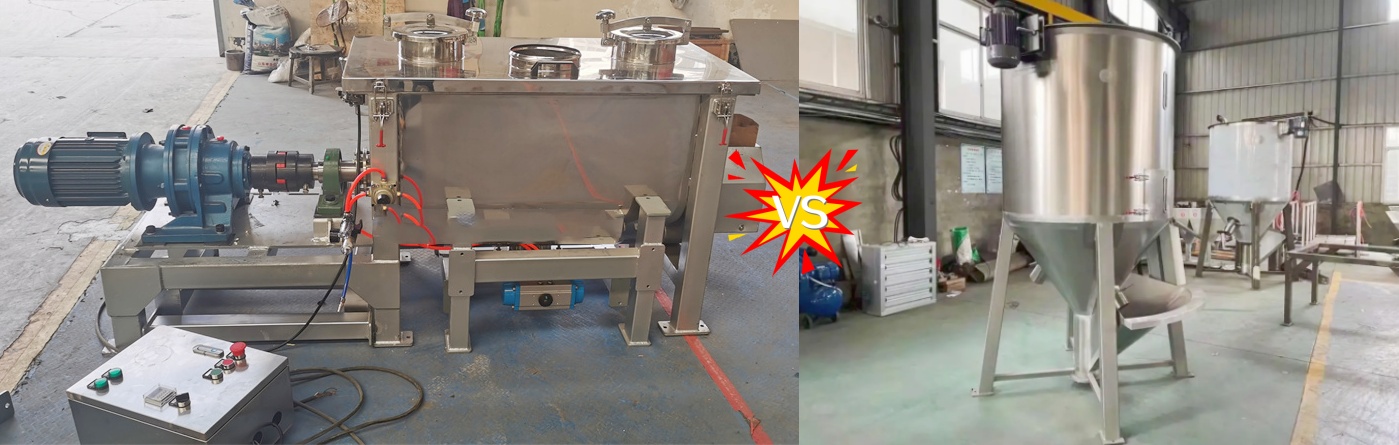

Horizontal and vertical mixers for vitamins and minerals differ significantly due to their different structural designs. Horizontal mixers utilize a horizontal barrel with twin ribbons for forced convection mixing, resulting in high uniformity and low residue. Vertical mixers utilize a vertical barrel with a bottom spiral for gravity mixing, requiring less space and lowering costs.

Structural Design: Horizontal mixers utilize a horizontally positioned mixing barrel with twin or multi-layered ribbon blades. This propulsion system creates a thorough horizontal convection circulation of the material. Vertical mixers, on the other hand, utilize a vertical barrel as their core structure, with a single spiral shaft. This rapidly rotating shaft lifts the material from the bottom to the top, where it is then dispersed back to the bottom in an umbrella-like pattern, creating a vertical tumbling mixing process.

Operating Principle: Horizontal mixers utilize a 360-degree dual S-shaped ribbon blade design to create synchronized axial and radial mixing, forming a three-dimensional, complex circulation path. Vertical mixers rely on the vertical rotation of the spiral shaft to achieve vertical circulation of the material, primarily through localized convection.

Mixing Performance and Material Compatibility: Horizontal mixers achieve mixing uniformity exceeding 99% with extremely low residue, making them particularly suitable for high-precision mixing of viscous and fine-grained materials. Vertical mixers typically achieve uniformity around 90% with higher residue, but are more suitable for handling hard, coarse-grained materials.

Cost and Maintenance: Horizontal mixers have a higher initial investment, but due to the location of the rotating bearings on both sides of the equipment, maintenance rates are low. Vertical mixers have a significant price advantage, but the location of the rotating bearings at the bottom of the equipment increases maintenance frequency, making them more suitable for individual users with smaller investments and initial cost sensitivity.

Vitamins and minerals for horizontal mixer are used across multiple industries, helping companies solve mixing challenges. We can customize production solutions based on our customers' production needs.

A food supplement factory: This facility produces compressed candies and meal replacement powders containing vitamins A and D, as well as calcium and iron. Previously, uneven mixing in the equipment resulted in fluctuating tablet content, and prolonged cleaning time impacted production capacity. After upgrading to a 300L stainless steel horizontal ribbon mixer, the dual-ribbon forced convection design reduced mixing uniformity to below 3%, meeting FDA and GMP standards.

Livestock and Poultry Feed Premixes: This facility processes premixes of vitamins A and D3, as well as minerals such as copper and manganese, requiring minimal cross-contamination and accurate raw material traceability. An automated horizontal mixer system with 54 silos ensures precise batching using a three-stage weighing unit. After screening and impurity removal, the material is automatically transported to the mixer by an automated guided vehicle (AGV). The equipment's U-shaped chamber and double-ribbon structure achieve a residual rate of ≤0.3%, with a mixing time of 8 minutes.

Pharmaceutical-grade premix production:The need for enhanced production automation and ingredient traceability was realized without interrupting production. An automated horizontal mixing system with 30 raw material silos was introduced, utilizing three levels of batching for large, medium, and micro quantities, along with integrated material conveying and packaging lines. The 316L stainless steel chamber and sealed design minimized ingredient loss, achieving a mixing uniformity of 99%. The equipment control system automatically generated production reports, fully meeting the pharmaceutical company's stringent ingredient traceability requirements.

Handling the Vitamins and Minerals for Horizontal Mixers requires strict adherence to procedures. Pre-startup inspections are required, and the speed and feed rate must be controlled during operation. Maintenance requires regular cleaning of the chamber, lubrication of transmission components, and timely replacement of wearing parts.

Operation: Add vitamins, minerals and other raw materials accurately according to the formula requirements, and start the mixer for mixing. Clean the equipment after mixing to avoid cross contamination of different batches of feed.

Maintenance: Check the agitator and transmission parts regularly, keep them lubricated, and avoid malfunctions. Pay attention to safe operation to avoid foreign matter from entering the mixing barrel and affecting the mixing effect.

Dahan Machinery's Vitamins and minerals for horizontal mixer are widely used in the pharmaceutical, health supplement, and food additive industries. Utilizing 304/316L stainless steel, combined with a dual-shaft ribbon impeller and three-dimensional circulation design, we ensure a mixing uniformity of over 99% for vitamins, minerals, and other trace ingredients, with a residual rate of less than 0.5%. The equipment supports customized production, with capacities ranging from 2 to 20 cubic meters. Equipped with an intelligent control system and side viewing ports, it meets the needs of small, medium, and large-scale production.

Vitamins and minerals for horizontal mixer plays an important role in livestock and poultry feed production, and its efficient mixing function and convenient operation characteristics have attracted widespread attention. Through the reasonable use and maintenance of the mixer, manufacturers can optimize feed formulas and improve production efficiency, while providing livestock and poultry with nutritionally balanced feed to promote the healthy growth of livestock and poultry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.