Vertical screw mixer is a kind of equipment commonly used for mixing solids and powders. It has the characteristics of efficient mixing, good uniformity and easy operation. Solids and powders vertical screw mixer is a piece of equipment designed based on the mixing process requirements and based on the valuable opinions of users over the years. Based on the original model and combined with actual needs, this machine improves the reduction system and adopts an advanced two-stage dual-axis cycloidal pinwheel reducer. All of this improves mixing range, productivity and service life. At the same time, according to process requirements, the machine can be equipped with stepless speed regulation, and can be widely used in chemical, fertilizer, fuel, metallurgy, mining, food, monosodium glutamate, feed and other industries (mixing of solid and powder materials).

Feeding: Pour the solid or powder raw materials to be mixed into the vertical barrel.

Start the motor: Start the motor, and the transmission device drives the screw mixing blade to start rotating.

Mixing process: The spiral mixing blade rotates at high speed in the barrel, continuously throwing the raw materials upward, and then falling, forming a convection motion to achieve mixing.

Uniform mixing: The raw materials are continuously stirred, thrown up and dropped under the action of the screw mixing blades, and finally uniform mixing is achieved.

Stop mixing: After mixing is completed, stop the motor and take out the mixed raw materials.

Main structure: Solids and powders vertical screw mixer usually consists of a vertical barrel, screw mixing blades, motor, transmission device, etc.

Vertical barrel: usually cylindrical with a smooth interior to ensure that the raw materials do not stick during the mixing process.

Screw mixing blade: fixed on the main shaft, driven by the motor to rotate to mix the raw materials.

Motor and transmission device: provide power to rotate the screw mixing blades to complete the mixing process.

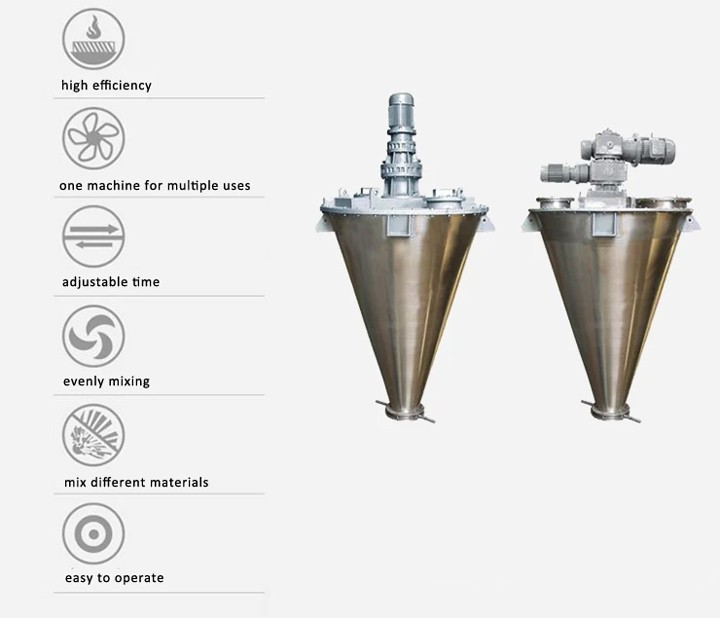

Efficient mixing: The spiral mixing blades can quickly mix raw materials and improve production efficiency when rotating at high speed.

Good uniformity: Through the action of the spiral stirring blades, the raw materials are continuously stirred, thrown up and dropped in the barrel to achieve uniform mixing and ensure stable product quality.

Easy operation: The operation is simple and intuitive. You only need to start the motor after feeding the materials to complete the mixing process, without complicated operating steps.

Strong applicability: The tapered cylinder is suitable for high-requirements of residue-free mixed materials, and the gentle stirring speed will not damage fragile materials.

Energy saving: It is driven by a motor, which can accurately control the mixing speed and time, saving energy consumption.

Easy to clean and maintain: Simple structure, convenient cleaning and maintenance, which can effectively reduce downtime during the production process.

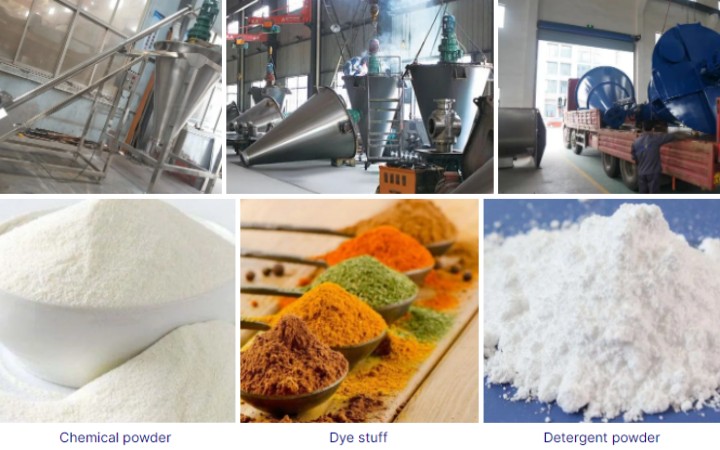

Chemical industry: used for mixing powder and granular chemical raw materials, such as pigments, dyes, powder coatings, etc.

Food industry: used for mixing food additives, seasonings, dried fruits and nuts and other food raw materials.

Pharmaceutical industry: used for mixing pharmaceutical raw materials, such as pharmaceutical powders, tablet ingredients, etc.

Building materials industry: used for mixing cement, lime, mortar and other building materials raw materials.

Agricultural field: used to mix feed raw materials, such as grains, soybean meal, vitamins, etc., to improve the nutritional balance of the feed.

Solids and powders vertical screw mixer has wide adaptability to mixed materials, no overheating for heat-sensitive materials, no pressure feeding and grinding for granular materials, and no chip separation for materials with different particle sizes. The tapered cylinder can meet high requirements for mixing materials without any problem. Residue. Solids and powders for vertical screw mixer can mix solid and powder raw materials quickly and evenly, and is widely used in the production process of multiple industries. The vertical spiral mixer produced by our manufacturer can be customized according to needs. To formulate a detailed proposal or quote, you can browse and consult our website.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.